Factory Cheap Hot High Power Thyristor - High Power Free Floating Phase Control Thyristor – Runau Electronics

Factory Cheap Hot High Power Thyristor - High Power Free Floating Phase Control Thyristor – Runau Electronics Detail:

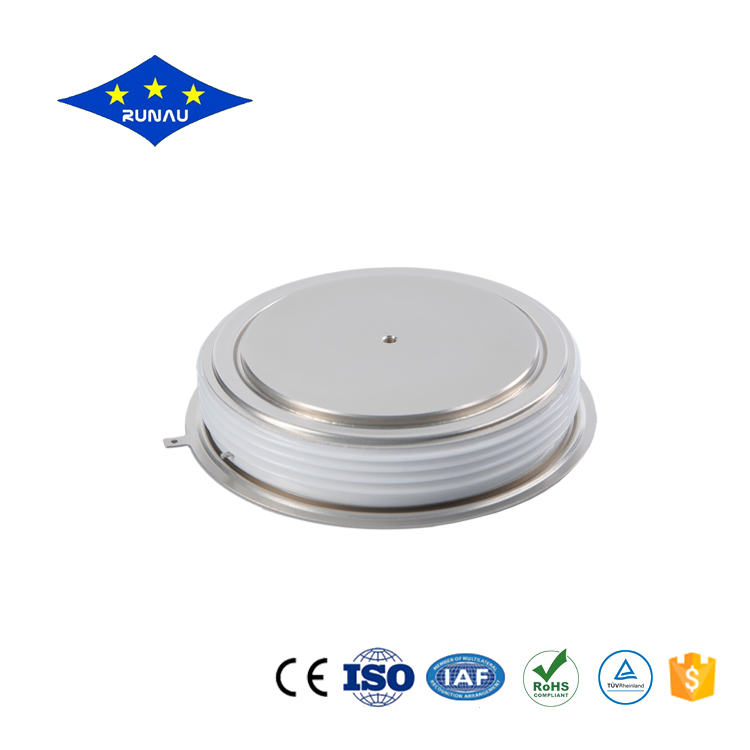

Phase Control Thyristor (Free Floating Type)

Description:

With the development of increasing power and capacity of converter equipment, especially HVDC transmission, the output power capacity of unit thyristor is request to increase accordingly, such will reduce the installation quantity of thyristor in series and parallel connection circuit. The device size and weight will be reduced, lower investment, even current and even voltage will be realized easily, the reliable operation and commercial value will be increased significantly.

The free floating silicon technology employed to manufacture high power high current thyristor will satisfy the high standard application requirement. And in 2019 July, RUNAU Electronics had developed 5200V thyristor with 5” chip successfully and supplied to customer which applied in China HVDC project.

Introduction:

1. Chip

The high standard thyristor chip manufactured by RUNAU Electronics is free floating technology applied. It’s the well acknowledged as the latest and mature technology for manufacturing the high power high voltage thyristor. It’s widely applied by the most world class manufactures.

The diffusion process was optimized in density and width to increase the voltage resistance, decrease the on-state voltage drop, and improve the trigger & dynamic characteristics. New photolithography pattern was designed to enhance the di/dt and dv/dt feature. Contact structure of chip was re-constructed to protect the edge of silicon wafer and cathode surface, the reverse voltage performance will be improved greatly.

2. Encapsulation

The advantage of free floating silicon technology is the deformation between silicon and molybdenum wafer restrained greatly and molybdenum wafer consumption reduced. While the flatness of silicon wafer and copper block of package are highly required as well the parallelism and roughness requirement are higher than alloying chip technology. By the continuous improving and innovation, RUNAU Electronic had overcome all the technical difficulties and barriers. The free floating technology, high power high voltage thyristor with reliable performance and commercial efficient solution was developed and provided to clients. Most of them are installed in the high power controllable rectifier, high voltage soft starter, HVDC power transmission, locomotive traction, dynamic reactive power compensation and pulse power application system.

Technical specification

- Phase controlled thyristor with alloy type chip manufactured by RUNAU Electronics, range of ITAV from 350A to 5580A and VDRM/VRRM from 3400V to 8500V.

- IGT, VGT and IH are the test values at 25℃, unless otherwise stated, all the other parameters are the test values under Tjm;

- I2t=I2F SM×tw/2, tw= Sinusoidal half wave current base width. At 50Hz, I2t=0.005I2FSM(A2S);

- At 60Hz: IFSM(8.3ms)=IFSM(10ms)×1.066,Tj=Tj; I2t(8.3ms)=I2t(10ms)×0.943,Tj=Tjm

Parameter:

| TYPE | IT(AV) A |

TC ℃ |

VDRRM/VRRM V |

ITSM @TVJIM&10msA |

I2t A2s |

VTM @IT&TJ=25℃ V / A |

Tjm ℃ |

Rjc ℃/W |

Rc-s ℃/W |

F KN |

m Kg |

CODE | |

| Voltage up to 4200V | |||||||||||||

| KP3170-** | 3170 | 70 | 3400~4200 | 52000 | 1.3×107 | 1.40 | 3000 | 125 | 0.008 | 0.002 | 70 | 1.45 | T15C |

| KP4310-** | 4310 | 70 | 3400~4200 | 60000 | 1.8×107 | 1.30 | 3000 | 125 | 0.006 | 0.002 | 90 | 2.90 | T17D |

| KP5580-** | 5580 | 70 | 3400~4200 | 90000 | 4.0×107 | 1.40 | 5000 | 125 | 0.004 | 0.001 | 120 | 3.60 | T18D |

| Voltage up to 5200V | |||||||||||||

| KP970-** | 970 | 70 | 4400~5200 | 13500 | 9.1×105 | 2.70 | 2000 | 125 | 0.022 | 0.005 | 22 | 0.60 | T8C |

| KP2080-** | 2080 | 70 | 4400~5200 | 29200 | 4.2×106 | 1.60 | 2000 | 125 | 0.010 | 0.003 | 60 | 1.10 | T13C |

| KP2780-** | 2780 | 70 | 4400~5200 | 42000 | 8.8×106 | 1.70 | 3000 | 125 | 0.008 | 0.002 | 70 | 1.45 | T15C |

| KP3910-** | 3910 | 65 | 4400~5200 | 55000 | 1.5×107 | 1.50 | 3000 | 125 | 0.006 | 0.002 | 90 | 2.90 | T17D |

| KP4750-** | 4750 | 70 | 4400~5200 | 8700 | 3.7×107 | 1.50 | 5000 | 110 | 0.004 | 0.001 | 120 | 3.60 | T18D |

| Voltage up to 6600V | |||||||||||||

| KP350-** | 350 | 70 | 5800~6600 | 4500 | 1.0×105 | 2.20 | 500 | 125 | 0.039 | 0.008 | 10 | 0.33 | T5C |

| KP730-** | 730 | 70 | 5800~6600 | 11800 | 6.9×105 | 2.20 | 1000 | 125 | 0.022 | 0.005 | 22 | 0.60 | T8C |

| KP1420-** | 1420 | 70 | 5800~6600 | 22400 | 2.5×106 | 2.10 | 1500 | 125 | 0.010 | 0.003 | 60 | 1.10 | T13C |

| KP1800-** | 1800 | 70 | 5400~6600 | 32000 | 5.1×106 | 1.90 | 1600 | 125 | 0.008 | 0.002 | 70 | 1.45 | T15C |

| KP2810-** | 2810 | 70 | 5800~6600 | 45000 | 1.0×107 | 2.00 | 3000 | 125 | 0.006 | 0.002 | 90 | 2.90 | T17D |

| KP4250-** | 4250 | 70 | 5800~6600 | 71400 | 2.5×107 | 1.70 | 3000 | 110 | 0.004 | 0.001 | 120 | 3.60 | T18D |

| Voltage up to 7200V | |||||||||||||

| KP300-** | 300 | 70 | 6800~7200 | 3400 | 5.8×104 | 2.40 | 500 | 115 | 0.039 | 0.008 | 10 | 0.40 | T5D |

| KP640-** | 640 | 70 | 6800~7200 | 9000 | 4.0×105 | 2.30 | 1000 | 115 | 0.022 | 0.005 | 22 | 0.65 | T8D |

| KP1150-** | 1150 | 70 | 6800~7200 | 18300 | 1.6×106 | 2.40 | 1500 | 115 | 0.010 | 0.003 | 60 | 1.30 | T13D |

| KP1510-** | 1510 | 70 | 6800~7200 | 26000 | 3.3×106 | 2.00 | 1600 | 115 | 0.008 | 0.002 | 70 | 1.85 | T15D |

| KP2640-** | 2640 | 70 | 6800~7200 | 40000 | 8.0×106 | 1.50 | 1500 | 115 | 0.006 | 0.002 | 90 | 2.90 | T17D |

| Voltage up to 8500V | |||||||||||||

| KP270-** | 270 | 70 | 7400~8500 | 2900 | 4.2×104 | 2.80 | 500 | 115 | 0.045 | 0.008 | 10 | 0.40 | T5D |

| KP580-** | 580 | 70 | 7400~8500 | 6000 | 1.8×105 | 2.60 | 1000 | 115 | 0.022 | 0.005 | 22 | 0.65 | T8D |

| KP1080-** | 1080 | 70 | 7400~8500 | 11300 | 6.3×105 | 2.80 | 1500 | 115 | 0.010 | 0.003 | 60 | 1.30 | T13D |

| KP1480-** | 1480 | 70 | 7400~8500 | 17000 | 1.4×106 | 2.10 | 1600 | 115 | 0.009 | 0.002 | 70 | 1.85 | T15D |

Product detail pictures:

Related Product Guide:

Thyristor Definition

We always work as a tangible team to ensure that we can provide you with the best quality and the best price for Factory Cheap Hot High Power Thyristor - High Power Free Floating Phase Control Thyristor – Runau Electronics , The product will supply to all over the world, such as: Czech, Italy, Netherlands, To create more creative products, maintain high-quality products and update not only our products but ourselves so as to keep us ahead of the world, and the last but most vital one: to make every client satisfied with everything we offer and to grow stronger together. To be the real winner, starts here!

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!