Leading Manufacturer for MF Induction Heating Melting Rolling - Fast Switch Thyristor – Runau Electronics

Leading Manufacturer for MF Induction Heating Melting Rolling - Fast Switch Thyristor – Runau Electronics Detail:

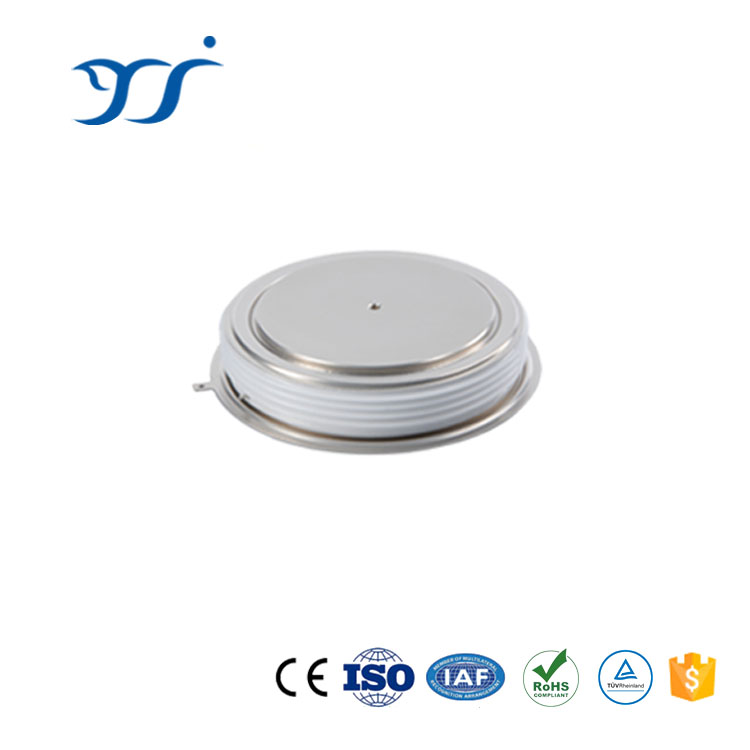

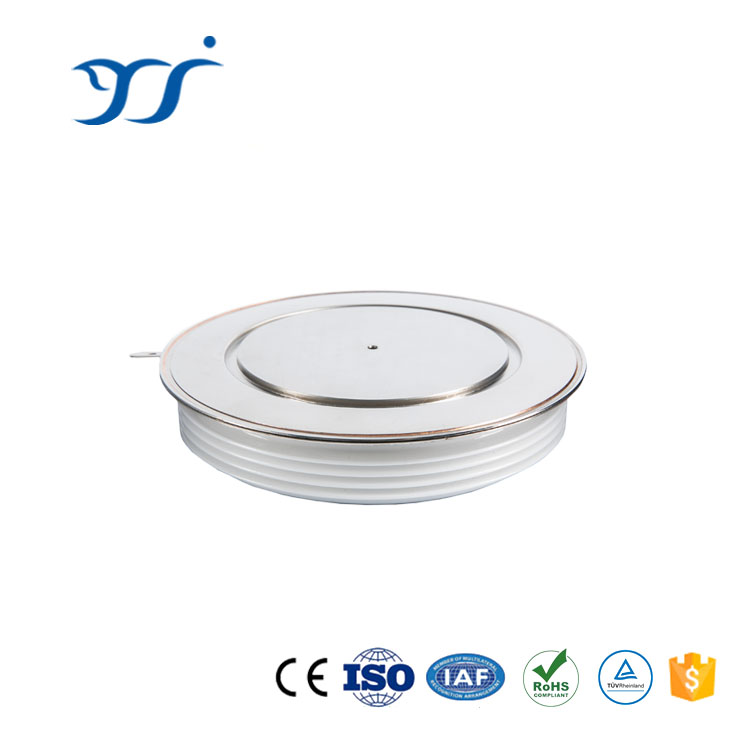

Fast Switch Thyristor

Description:

Fast switch thyristor, with the same structure and symbol of phase control thyristor, while the better static characteristics, especially dynamic characteristics is required by the high frequency application of rectification, chopping, inverter and frequency conversion circuit. The dynamic parameters of the fast thyristor are fast turn-on speed and turn-on expansion speed, less reverse recovery charge, and short turn-off time, high critical rise rate of on-state current (di/dt) and critical rate of rise of off-state voltage (dv/dt). The rated current of the fast thyristor within the rated frequency does not decrease or decreases a little when frequency increasing.

The fast switch thyristor manufacturing standard and processing technology of RUNAU Electronics was introduced from USA since 1980s, as a pioneer of manufacturing thyristor in China, the technical team of RUNAU had acquired the cutting-edge knowledge and ample manufacturing experience for more than 30 years. On basic of traditional manufacturing process, the talent technicians of RUNAU Electronics had developed the art-of-state technology in manufacturing thyristor with advantage features of European products, the quality and performance are improved greatly, more big wins achieved in the power electronics applications, and more value was created for partners.

Introduction:

1. Chip

The thyristor chip manufactured by RUNAU Electronics is sintered alloying technology employed. The silicon and molybdenum wafer was sintered for alloying by pure aluminum (99.999%) under high vacuum and high temperature environment. The administration of sintering characteristics is the key factor to affect the quality of thyristor. The know-how of RUNAU Electronics in addition to manage the alloy junction depth, surface flatness, alloy cavity as well full diffusion skill, ring circle pattern, special gate structure. Also the special processing was employed to reduce the carrier life of the device, so that the internal carrier recombination speed is greatly accelerated, the reverse recovery charge of the device is reduced, and the switching speed is improved consequently. Such measurements were applied to optimize the fast switching characteristics, on-state characteristics, and surge current property. The performance and conduction operation of thyristor is reliable and efficient.

2. Encapsulation

By strict controlling of flatness and parallelism of molybdenum wafer and external package, the chip and molybdenum wafer will be integrated with external package tightly and completely. Such will optimize the resistance of surge current and high short circuit current. And the measurement of electron evaporation technology was employed to create a thick aluminum film on silicon wafer surface, and ruthenium layer plated on molybdenum surface will enhance thermal fatigue resistance greatly, the work life time of fast switch thyristor will be increased significantly.

Technical specification

- Fast switch thyristor with alloy type chip manufactured by RUNAU Electronics, range of ITAV from 200A to 4000A and VDRM/VRRM from 1200V to 4500V.

- IGT, VGT and IH are the test values at 25℃, unless otherwise stated, all the other parameters are the test values under Tjm;

- I2t=I2F SM×tw/2, tw= Sinusoidal half wave current base width. At 50Hz, I2t=0.005I2FSM(A2S);

- At 60Hz: IFSM(8.3ms)=IFSM(10ms)×1.066,Tj=Tj; I2t(8.3ms)=I2t(10ms)×0.943,Tj=Tjm

Parameter:

| TYPE | IT(AV) A | TC ℃ | VDRRM/VRRM V | ITSM @TVJIM&10ms A | I2t A2s | VTM @IT&TJ=25℃ V / A | tq μs | Tjm ℃ | Rjc ℃/W | Rc-s ℃/W | F KN | m Kg | CODE | |

| Voltage up to 1400V | ||||||||||||||

| KK200-** | 200 | 55 | 1200~1400 | 2800 | 3.9×104 | 2.20 | 640 | 20 | 125 | 0.0600 | 0.0100 | 10 | 0.08 | T2A |

| KK500-** | 500 | 55 | 1200~1400 | 7500 | 2.8×105 | 2.00 | 1570 | 20 | 125 | 0.0390 | 0.0080 | 15 | 0.26 | T5C |

| KK800-** | 800 | 55 | 1200~1400 | 12000 | 7.2×105 | 2.00 | 2400 | 20 | 125 | 0.0300 | 0.0060 | 20 | 0.33 | T7C |

| KK1000-** | 1000 | 55 | 1200~1400 | 15000 | 1.1×106 | 2.00 | 3000 | 20 | 125 | 0.0220 | 0.0050 | 25 | 0.46 | T8C |

| KK1200-** | 1200 | 55 | 1200~1400 | 18000 | 1.6×106 | 2.00 | 3000 | 20 | 125 | 0.0200 | 0.0050 | 27 | 0.5 | T8C |

| KK1500-** | 1500 | 55 | 1200~1400 | 22500 | 2.5×106 | 1.90 | 3000 | 20 | 125 | 0.0160 | 0.0045 | 28 | 0.65 | T10C |

| KK1800-** | 1800 | 55 | 1200~1400 | 25200 | 3.2×106 | 1.90 | 3000 | 20 | 125 | 0.0150 | 0.0045 | 30 | 0.72 | T11C |

| KK2400-** | 2400 | 55 | 1200~1400 | 33600 | 5.6×106 | 1.70 | 3000 | 22 | 125 | 0.0120 | 0.0040 | 33 | 0.72 | T11C |

| KK3000-** | 3000 | 55 | 1200~1400 | 42000 | 8.8×106 | 1.60 | 3000 | 22 | 125 | 0.0100 | 0.0030 | 35 | 0.72 | T13C |

| Voltage up to 2000V | ||||||||||||||

| KK500-** | 500 | 55 | 1600~2000 | 7000 | 2.5×105 | 2.50 | 1570 | 30 | 125 | 0.0390 | 0.0080 | 15 | 0.26 | T5C |

| KK800-** | 800 | 55 | 1600~2000 | 11200 | 6.3×105 | 2.60 | 2400 | 30 | 125 | 0.0300 | 0.0060 | 20 | 0.33 | T7C |

| KK1000-** | 1000 | 55 | 1600~2000 | 14000 | 9.8×105 | 2.40 | 3000 | 30 | 125 | 0.0220 | 0.0050 | 25 | 0.46 | T8C |

| KK1200-** | 1200 | 55 | 1600~2000 | 16800 | 1.4×106 | 2.30 | 3000 | 30 | 125 | 0.0200 | 0.0050 | 27 | 0.5 | T8C |

| KK1500-** | 1500 | 55 | 1600~2000 | 21000 | 2.2×106 | 2.20 | 3000 | 30 | 125 | 0.0160 | 0.0050 | 28 | 0.65 | T9C |

| KK1800-** | 1800 | 55 | 1600~2000 | 25200 | 3.2×106 | 2.10 | 3000 | 35 | 125 | 0.0150 | 0.0045 | 30 | 0.72 | T11C |

| KK2000-** | 2000 | 55 | 1600~2000 | 28000 | 3.9×106 | 2.00 | 3000 | 35 | 125 | 0.0125 | 0.0040 | 33 | 0.85 | T11C |

| KK2700-** | 2700 | 55 | 1600~2000 | 37800 | 7.1×106 | 1.90 | 3000 | 40 | 125 | 0.0100 | 0.0030 | 35 | 1.1 | T13C |

| KK3600-** | 3600 | 55 | 1600~2000 | 50400 | 12.5×106 | 1.40 | 3000 | 40 | 125 | 0.0080 | 0.0020 | 60 | 1.3 | T14C |

| Voltage up to 3000V | ||||||||||||||

| KK1000-** | 1000 | 55 | 2500~3000 | 12000 | 7.2×105 | 2.90 | 3000 | 55 | 125 | 0.0220 | 0.0050 | 25 | 0.46 | T8C |

| KK1200-** | 1200 | 55 | 2500~3000 | 14400 | 1.0×106 | 2.80 | 3001 | 55 | 125 | 0.0200 | 0.0050 | 27 | 0.5 | T8C |

| KK1500-** | 1500 | 55 | 2500~3000 | 18500 | 1.7×106 | 2.70 | 3002 | 60 | 125 | 0.0160 | 0.0050 | 28 | 0.65 | T9C |

| KK1800-** | 1800 | 55 | 2500~3000 | 21600 | 2.3×106 | 2.60 | 3003 | 60 | 125 | 0.0150 | 0.0045 | 30 | 0.72 | T11C |

| KK2000-** | 2000 | 55 | 2500~3000 | 24000 | 2.9×106 | 2.40 | 3004 | 60 | 125 | 0.0125 | 0.0040 | 33 | 0.85 | T11C |

| KK2500-** | 2500 | 55 | 2500~3000 | 30000 | 4.5×106 | 2.20 | 3005 | 60 | 125 | 0.0100 | 0.0030 | 35 | 1.1 | T13C |

| KK3000-** | 3000 | 55 | 2500~3000 | 36000 | 6.5×106 | 1.90 | 3006 | 60 | 125 | 0.0080 | 0.0020 | 60 | 1.4 | T15C |

| KK4000-** | 4000 | 55 | 2500~3000 | 48000 | 1.2×107 | 1.80 | 3007 | 60 | 125 | 0.0060 | 0.0015 | 80 | 1.9 | T16D |

| Voltage up to 3500V | ||||||||||||||

| KK1800-** | 1800 | 55 | 3200~3500 | 21600 | 2.3×106 | 2.90 | 3000 | 80 | 125 | 0.0100 | 0.0030 | 35 | 1.1 | T13C |

| KK2500-** | 2500 | 55 | 3200~3500 | 30000 | 4.5×106 | 2.50 | 3000 | 80 | 125 | 0.0080 | 0.0020 | 60 | 1.4 | T15C |

| Voltage up to 4500V | ||||||||||||||

| KK3708-** | 3708 | 55 | 4500 | 50000 | 1.3×107 | 2.10 | 4000 | 250 | 125 | 0.0060 | 0.0015 | 80 | 1.9 | T16D |

Product detail pictures:

Related Product Guide:

Thyristor Definition

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Leading Manufacturer for MF Induction Heating Melting Rolling - Fast Switch Thyristor – Runau Electronics , The product will supply to all over the world, such as: Australia, Hanover, Botswana, We offer the great variety of products in this field. Besides, customized orders are also available. What's more, you will enjoy our excellent services. In one word, your satisfaction is guaranteed. Welcome to visit our company! For more information, please come to our website.If any further inquiries, please feel free to contact us.

The customer service staff's answer is very meticulous, the most important is that the product quality is very good, and packaged carefully, shipped quickly!