OEM/ODM Factory Fast Turn-Off Thyristors - High Standard Fast Switch Thyristor – Runau Electronics

OEM/ODM Factory Fast Turn-Off Thyristors - High Standard Fast Switch Thyristor – Runau Electronics Detail:

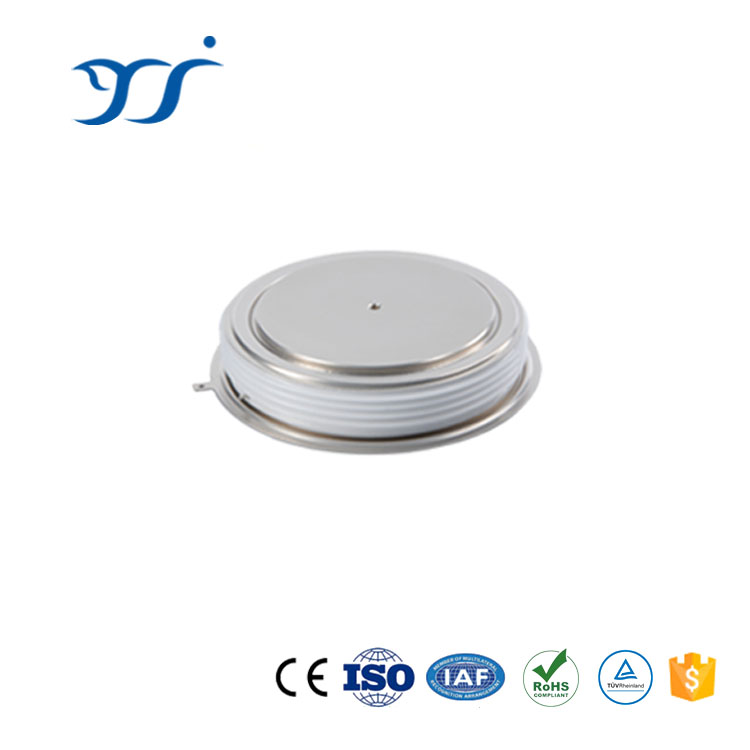

Fast Switch Thyristor (high standard YC series)

Description

The GE manufacturing standard and processing technology was introduced and employed by RUNAU Electronics since 1980s. The complete manufacturing and testing condition were completely coinciding with the requirement of USA market requirement. As a pioneer of manufacturing thyristor in China, RUNAU Electronics had provided the art of state power electronics devices to USA, European countries and global users. It’s highly qualified and appraised by the clients and more big wins and value were created for partners.

Introduction:

1. Chip

The thyristor chip manufactured by RUNAU Electronics is sintered alloying technology employed. The silicon and molybdenum wafer was sintered for alloying by pure aluminum (99.999%) under high vacuum and high temperature environment. The administration of sintering characteristics is the key factor to affect the quality of thyristor. The know-how of RUNAU Electronics in addition to manage the alloy junction depth, surface flatness, alloy cavity as well full diffusion skill, ring circle pattern, special gate structure. Also the special processing was employed to reduce the carrier life of the device, so that the internal carrier recombination speed is greatly accelerated, the reverse recovery charge of the device is reduced, and the switching speed is improved consequently. Such measurements were applied to optimize the fast switching characteristics, on-state characteristics, and surge current property. The performance and conduction operation of thyristor is reliable and efficient.

2. Encapsulation

By strict controlling of flatness and parallelism of molybdenum wafer and external package, the chip and molybdenum wafer will be integrated with external package tightly and completely. Such will optimize the resistance of surge current and high short circuit current. And the measurement of electron evaporation technology was employed to create a thick aluminum film on silicon wafer surface, and ruthenium layer plated on molybdenum surface will enhance thermal fatigue resistance greatly, the work life time of fast switch thyristor will be increased significantly.

Technical specification

- Fast switch thyristor with alloy type chip manufactured by RUNAU Electronics capable to provide the fully qualified products of USA standard.

- IGT, VGT and IH are the test values at 25℃, unless otherwise stated, all the other parameters are the test values under Tjm;

- I2t=I2F SM×tw/2, tw= Sinusoidal half wave current base width. At 50Hz, I2t=0.005I2FSM(A2S);

- At 60Hz: IFSM(8.3ms)=IFSM(10ms)×1.066,Tj=Tj; I2t(8.3ms)=I2t(10ms)×0.943,Tj=Tjm

Parameter:

| TYPE | IT(AV) A |

TC ℃ |

VDRRM/VRRM V |

ITSM @TVJIM&10ms A |

I2t A2s |

VTM @IT&TJ=25℃ V / A |

tq μs |

Tjm ℃ |

Rjc ℃/W |

Rc-s ℃/W |

F KN |

m Kg |

CODE | |

| Voltage up to 1600V | ||||||||||||||

| YC476 | 380 | 55 | 1200~1600 | 5320 | 1.4×105 | 2.90 | 1500 | 30 | 125 | 0.054 | 0.010 | 10 | 0.08 | T2A |

| YC448 | 700 | 55 | 1200~1600 | 8400 | 3.5×105 | 2.90 | 2000 | 35 | 125 | 0.039 | 0.008 | 15 | 0.26 | T5C |

| Voltage up to 2000V | ||||||||||||||

| YC712 | 1000 | 55 | 1600~2000 | 14000 | 9.8×105 | 2.20 | 3000 | 55 | 125 | 0.022 | 0.005 | 25 | 0.46 | T8C |

| YC770 | 2619 | 55 | 1600~2000 | 31400 | 4.9×106 | 1.55 | 2000 | 70 | 125 | 0.011 | 0.003 | 35 | 1.5 | T13D |

Product detail pictures:

Related Product Guide:

Thyristor Definition

We offer fantastic energy in high quality and enhancement,merchandising,profits and promoting and procedure for OEM/ODM Factory Fast Turn-Off Thyristors - High Standard Fast Switch Thyristor – Runau Electronics , The product will supply to all over the world, such as: Tajikistan, Finland, Mongolia, As an experienced factory we also accept customized order and make it same as your picture or sample specifying specification and customer design packing. The main goal of the company is to live a satisfactory memory to all the customers, and establish a long term win-win business relationship. For more information, please contact us. And It is our great pleasure if you like to have a personally meeting in our office.

The product manager is a very hot and professional person, we have a pleasant conversation, and finally we reached a consensus agreement.